| Availability: | |

|---|---|

| Quantity: | |

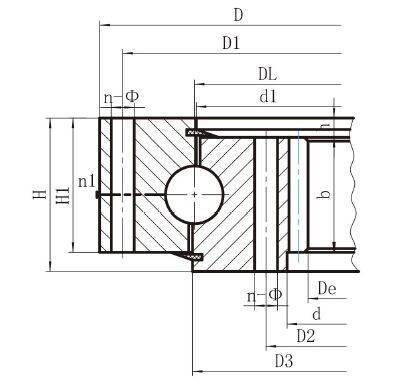

The single row four point contact ball slewing rings is composed of two seat rings, which design in compact structure, steel ball contact with the circular raceway at four points; it can bear the axial force, radial force and the tilting moment at the same time.

It can be used for slewing conveyer, welding manipulator, light & medium duty crane, excavator, and other construction machinery.

Tytle:Single Row Four Point Contact Ball Slewing Bearing Internal Gear

Wight/KG:100-8760

To get drawing (pdf),please clik on Model.

To get drawing (pdf),please clik on Model.

No | Model | Dimensions | Mounting Dimensions | Structural Dimensions | Gear data | Gear force | Weight | |||||||||||||

D | d | H | D1 | D2 | n | mm | n1 | D3 | d1 | H1 | h | b | x | m | De | z | Tempering | |||

1 | HSN.25.625 | 725 | 525 | 80 | 685 | 565 | 18 | 18 | 3 | 626 | 624 | 68 | 12 | 60 | 1.4 | 5 | 498.8 | 101 | 5.2 | 100 |

| 1.15 | 6 | 496.7 | 84 | 6.2 | |||||||||||||||

2 | HSN.25.720 | 820 | 620 | 80 | 780 | 660 | 18 | 18 | 3 | 721 | 719 | 68 | 12 | 60 | 1.4 | 6 | 586.6 | 99 | 6.2 | 120 |

| 1 | 8 | 582.3 | 74 | 8.3 | |||||||||||||||

3 | HSN.30.820 | 940 | 705 | 95 | 893 | 749 | 24 | 20 | 4 | 821 | 818 | 83 | 12 | 70 | 1.4 | 6 | 664.5 | 112 | 7.2 | 210 |

| 1 | 10 | 658 | 67 | 12.2 | |||||||||||||||

4 | HSN.30.880 | 1000 | 760 | 95 | 956 | 800 | 24 | 20 | 4 | 881 | 878 | 83 | 12 | 70 | 1.15 | 8 | 718.2 | 91 | 9.7 | 230 |

| 1 | 10 | 707.9 | 72 | 12.2 | |||||||||||||||

5 | HSN.30.1020 | 1170 | 875 | 95 | 1120 | 930 | 24 | 22 | 4 | 1021 | 1018 | 80 | 15 | 70 | 1.4 | 8 | 830.1 | 105 | 9.7 | 300 |

| 1.15 | 10 | 827.8 | 84 | 12.2 | |||||||||||||||

6 | HSN.30.1220 | 1365 | 1075 | 120 | 1310 | 1130 | 36 | 24 | 6 | 1221 | 1218 | 105 | 15 | 90 | 1.4 | 10 | 1027.8 | 104 | 15.7 | 450 |

| 1 | 12 | 1017.3 | 86 | 18.8 | |||||||||||||||

7 | HSN.35.1250 | 1400 | 1090 | 120 | 1350 | 1150 | 36 | 26 | 6 | 1251 | 1248 | 105 | 15 | 90 | -0.35 | 10 | 1037 | 105 | 15.7 | 520 |

| 1 | 12 | 1028.8 | 87 | 18.8 | |||||||||||||||

8 | HSN.35.1435 | 1595 | 1278 | 120 | 1535 | 1335 | 36 | 26 | 6 | 1436 | 1433 | 105 | 15 | 90 | 1.15 | 12 | 1221.2 | 103 | 18.8 | 610 |

| 1 | 14 | 1214.8 | 88 | 21.9 | |||||||||||||||

9 | HSN.35.1540 | 1720 | 1360 | 140 | 1660 | 1420 | 42 | 26 | 6 | 1541 | 1538 | 122 | 18 | 110 | 1.4 | 12 | 1293.1 | 109 | 23 | 732 |

| 1.15 | 14 | 1284.8 | 93 | 26.8 | |||||||||||||||

10 | HSN.35.1700 | 1875 | 1525 | 140 | 1815 | 1585 | 42 | 29 | 6 | 1701 | 1698 | 122 | 18 | 110 | 1.15 | 14 | 1452.7 | 105 | 26.8 | 844 |

| 1.15 | 16 | 1452.3 | 92 | 30.5 | |||||||||||||||

11 | HSN.40.1880 | 2100 | 1665 | 160 | 2030 | 1740 | 48 | 32 | 6 | 1881 | 1878 | 140 | 20 | 115 | 1.4 | 14 | 1592.6 | 115 | 27.8 | 1400 |

| 1.15 | 18 | 1579.9 | 89 | 35.8 | |||||||||||||||

12 | HSN.40.2115 | 2325 | 1900 | 160 | 2245 | 1980 | 48 | 32 | 6 | 2116 | 2113 | 140 | 20 | 115 | 1.4 | 16 | 1804.1 | 114 | 31.9 | 1600 |

HSN.40.2115A | 1.15 | 20 | 1795.4 | 91 | 40 | |||||||||||||||

13 | HSN.40.2370 | 2600 | 2146 | 180 | 2520 | 2220 | 48 | 32 | 6 | 2371 | 2368 | 158 | 22 | 130 | 1.4 | 18 | 2065.6 | 116 | 40.7 | 2100 |

HSN.40.2370A | 1.15 | 22 | 2040.9 | 94 | 49.7 | |||||||||||||||

14 | HSN.40.2600 | 2835 | 2365 | 180 | 2750 | 2450 | 54 | 36 | 6 | 2601 | 2598 | 158 | 22 | 130 | 1.4 | 18 | 2263.5 | 127 | 37.6 | 2400 |

HSN.40.2600A | 1.15 | 22 | 2260.8 | 104 | 45.9 | |||||||||||||||

15 | HSN.50.2820 | 3085 | 2555 | 200 | 3000 | 2640 | 54 | 36 | 6 | 2822 | 2818 | 178 | 22 | 150 | 1.4 | 20 | 2455 | 124 | 52.2 | 3400 |

HSN.50.2820A | 1.15 | 25 | 2444.1 | 99 | 65.3 | |||||||||||||||

16 | HSN.50.3120 | 3400 | 2840 | 200 | 3310 | 2930 | 54 | 36 | 6 | 3122 | 3118 | 178 | 22 | 150 | 1.4 | 22 | 2722.5 | 125 | 57.4 | 4000 |

HSN.50.3120A | 1.4 | 25 | 2719 | 110 | 65.3 | |||||||||||||||

17 | HSN.50.3580 | 3920 | 3240 | 240 | 3820 | 3340 | 60 | 40 | 6 | 3582 | 3578 | 218 | 22 | 190 | 1.4 | 22 | 3118.4 | 143 | 72.7 | 6700 |

HSN.50.3580A | 1.4 | 25 | 3118.8 | 126 | 82.6 | |||||||||||||||

18 | HSN.50.4030 | 4370 | 3690 | 240 | 4270 | 3790 | 66 | 40 | 6 | 4032 | 4028 | 218 | 22 | 190 | 1.4 | 22 | 3558.3 | 163 | 53.6 | 7700 |

HSN.50.4030A | 1.4 | 28 | 3549 | 128 | 68.2 | |||||||||||||||

19 | HSN.50.4540 | 4860 | 4210 | 240 | 4760 | 4310 | 72 | 40 | 6 | 4542 | 4538 | 218 | 22 | 190 | 1.4 | 22 | 4042.2 | 185 | 72.1 | 8760 |

HSN.50.4540A | 1.4 | 30 | 4042.4 | 136 | 99.1 | |||||||||||||||

Note:

1. N1 is the numbers of lubricating holes. Oil cup M10×1JB/T7940.1~JB/T7940.2

2. n-φ can change to tapped hole, tooth width can change to H-h.

3. The tangential tooth force in the form is the max tooth force; the nominal tangential tooth force is 1/2 of the max one.

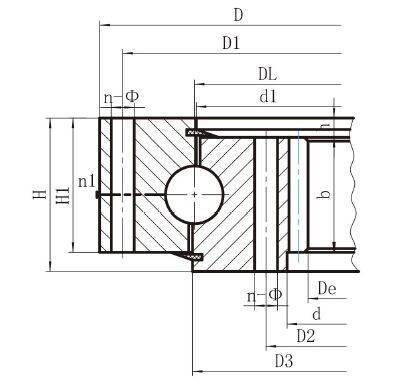

The single row four point contact ball slewing rings is composed of two seat rings, which design in compact structure, steel ball contact with the circular raceway at four points; it can bear the axial force, radial force and the tilting moment at the same time.

It can be used for slewing conveyer, welding manipulator, light & medium duty crane, excavator, and other construction machinery.

Tytle:Single Row Four Point Contact Ball Slewing Bearing Internal Gear

Wight/KG:100-8760

To get drawing (pdf),please clik on Model.

To get drawing (pdf),please clik on Model.

No | Model | Dimensions | Mounting Dimensions | Structural Dimensions | Gear data | Gear force | Weight | |||||||||||||

D | d | H | D1 | D2 | n | mm | n1 | D3 | d1 | H1 | h | b | x | m | De | z | Tempering | |||

1 | HSN.25.625 | 725 | 525 | 80 | 685 | 565 | 18 | 18 | 3 | 626 | 624 | 68 | 12 | 60 | 1.4 | 5 | 498.8 | 101 | 5.2 | 100 |

| 1.15 | 6 | 496.7 | 84 | 6.2 | |||||||||||||||

2 | HSN.25.720 | 820 | 620 | 80 | 780 | 660 | 18 | 18 | 3 | 721 | 719 | 68 | 12 | 60 | 1.4 | 6 | 586.6 | 99 | 6.2 | 120 |

| 1 | 8 | 582.3 | 74 | 8.3 | |||||||||||||||

3 | HSN.30.820 | 940 | 705 | 95 | 893 | 749 | 24 | 20 | 4 | 821 | 818 | 83 | 12 | 70 | 1.4 | 6 | 664.5 | 112 | 7.2 | 210 |

| 1 | 10 | 658 | 67 | 12.2 | |||||||||||||||

4 | HSN.30.880 | 1000 | 760 | 95 | 956 | 800 | 24 | 20 | 4 | 881 | 878 | 83 | 12 | 70 | 1.15 | 8 | 718.2 | 91 | 9.7 | 230 |

| 1 | 10 | 707.9 | 72 | 12.2 | |||||||||||||||

5 | HSN.30.1020 | 1170 | 875 | 95 | 1120 | 930 | 24 | 22 | 4 | 1021 | 1018 | 80 | 15 | 70 | 1.4 | 8 | 830.1 | 105 | 9.7 | 300 |

| 1.15 | 10 | 827.8 | 84 | 12.2 | |||||||||||||||

6 | HSN.30.1220 | 1365 | 1075 | 120 | 1310 | 1130 | 36 | 24 | 6 | 1221 | 1218 | 105 | 15 | 90 | 1.4 | 10 | 1027.8 | 104 | 15.7 | 450 |

| 1 | 12 | 1017.3 | 86 | 18.8 | |||||||||||||||

7 | HSN.35.1250 | 1400 | 1090 | 120 | 1350 | 1150 | 36 | 26 | 6 | 1251 | 1248 | 105 | 15 | 90 | -0.35 | 10 | 1037 | 105 | 15.7 | 520 |

| 1 | 12 | 1028.8 | 87 | 18.8 | |||||||||||||||

8 | HSN.35.1435 | 1595 | 1278 | 120 | 1535 | 1335 | 36 | 26 | 6 | 1436 | 1433 | 105 | 15 | 90 | 1.15 | 12 | 1221.2 | 103 | 18.8 | 610 |

| 1 | 14 | 1214.8 | 88 | 21.9 | |||||||||||||||

9 | HSN.35.1540 | 1720 | 1360 | 140 | 1660 | 1420 | 42 | 26 | 6 | 1541 | 1538 | 122 | 18 | 110 | 1.4 | 12 | 1293.1 | 109 | 23 | 732 |

| 1.15 | 14 | 1284.8 | 93 | 26.8 | |||||||||||||||

10 | HSN.35.1700 | 1875 | 1525 | 140 | 1815 | 1585 | 42 | 29 | 6 | 1701 | 1698 | 122 | 18 | 110 | 1.15 | 14 | 1452.7 | 105 | 26.8 | 844 |

| 1.15 | 16 | 1452.3 | 92 | 30.5 | |||||||||||||||

11 | HSN.40.1880 | 2100 | 1665 | 160 | 2030 | 1740 | 48 | 32 | 6 | 1881 | 1878 | 140 | 20 | 115 | 1.4 | 14 | 1592.6 | 115 | 27.8 | 1400 |

| 1.15 | 18 | 1579.9 | 89 | 35.8 | |||||||||||||||

12 | HSN.40.2115 | 2325 | 1900 | 160 | 2245 | 1980 | 48 | 32 | 6 | 2116 | 2113 | 140 | 20 | 115 | 1.4 | 16 | 1804.1 | 114 | 31.9 | 1600 |

HSN.40.2115A | 1.15 | 20 | 1795.4 | 91 | 40 | |||||||||||||||

13 | HSN.40.2370 | 2600 | 2146 | 180 | 2520 | 2220 | 48 | 32 | 6 | 2371 | 2368 | 158 | 22 | 130 | 1.4 | 18 | 2065.6 | 116 | 40.7 | 2100 |

HSN.40.2370A | 1.15 | 22 | 2040.9 | 94 | 49.7 | |||||||||||||||

14 | HSN.40.2600 | 2835 | 2365 | 180 | 2750 | 2450 | 54 | 36 | 6 | 2601 | 2598 | 158 | 22 | 130 | 1.4 | 18 | 2263.5 | 127 | 37.6 | 2400 |

HSN.40.2600A | 1.15 | 22 | 2260.8 | 104 | 45.9 | |||||||||||||||

15 | HSN.50.2820 | 3085 | 2555 | 200 | 3000 | 2640 | 54 | 36 | 6 | 2822 | 2818 | 178 | 22 | 150 | 1.4 | 20 | 2455 | 124 | 52.2 | 3400 |

HSN.50.2820A | 1.15 | 25 | 2444.1 | 99 | 65.3 | |||||||||||||||

16 | HSN.50.3120 | 3400 | 2840 | 200 | 3310 | 2930 | 54 | 36 | 6 | 3122 | 3118 | 178 | 22 | 150 | 1.4 | 22 | 2722.5 | 125 | 57.4 | 4000 |

HSN.50.3120A | 1.4 | 25 | 2719 | 110 | 65.3 | |||||||||||||||

17 | HSN.50.3580 | 3920 | 3240 | 240 | 3820 | 3340 | 60 | 40 | 6 | 3582 | 3578 | 218 | 22 | 190 | 1.4 | 22 | 3118.4 | 143 | 72.7 | 6700 |

HSN.50.3580A | 1.4 | 25 | 3118.8 | 126 | 82.6 | |||||||||||||||

18 | HSN.50.4030 | 4370 | 3690 | 240 | 4270 | 3790 | 66 | 40 | 6 | 4032 | 4028 | 218 | 22 | 190 | 1.4 | 22 | 3558.3 | 163 | 53.6 | 7700 |

HSN.50.4030A | 1.4 | 28 | 3549 | 128 | 68.2 | |||||||||||||||

19 | HSN.50.4540 | 4860 | 4210 | 240 | 4760 | 4310 | 72 | 40 | 6 | 4542 | 4538 | 218 | 22 | 190 | 1.4 | 22 | 4042.2 | 185 | 72.1 | 8760 |

HSN.50.4540A | 1.4 | 30 | 4042.4 | 136 | 99.1 | |||||||||||||||

Note:

1. N1 is the numbers of lubricating holes. Oil cup M10×1JB/T7940.1~JB/T7940.2

2. n-φ can change to tapped hole, tooth width can change to H-h.

3. The tangential tooth force in the form is the max tooth force; the nominal tangential tooth force is 1/2 of the max one.

Home | About Us | Products | News | Application | Support | Contact Us