Views: 60 Author: Site Editor Publish Time: 2021-06-19 Origin: Site

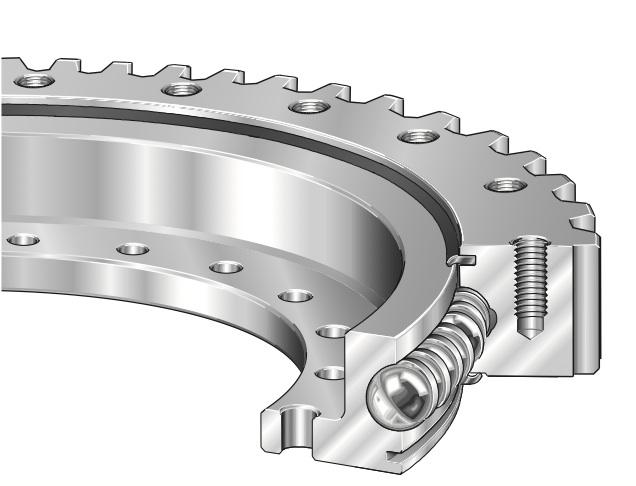

The raceways of slewing bearings usually require heat treatment. The usual process is: forging → rough machining → machining → finishing → raceway surface quenching → raceway surface milling and other processes. In the raceway, the flame surface quenching will form a soft zone. The so-called "soft zone" is an area that has not been heat-treated. Heat treatment will inevitably form a soft zone. In the final heat treatment process, due to the large diameter of the raceway of the slewing ring, we usually use flame surface quenching treatment. This is by using acetylene to heat the surface of the workpiece that needs to be quenched. After heating, the surface should be quenched immediately. The heating flame spray gun is installed together with the water spray gun. The mop moves cyclically on the circumference of the workpiece at the same time. When the movement is close to 360 degrees, please stop heating and cooling immediately. This means that there is no overlap in the circular area of heating and spraying. If overlap occurs in the circular area (the heat treatment angle on the circle is greater than 360 degrees), cracks will occur in the workpiece. The width of the untreated area along the tangent line is usually 15 mm. This 15 mm area is called the "soft area" in the slewing bearing.

Under normal circumstances, in the case of a soft zone in the manufacture of a workpiece, there will be a steel letter "S" to mark the specific position of the soft zone. All ordinary products have this very important mark. Essentially, the requirement of the soft zone installation location is to increase the service life of the bearing. From the perspective of the end user and the manufacturer, it is best to install the soft zone correctly. Therefore, the manufacturer of the slewing bearing should mark the location of the soft zone correctly and accurately. The installer of the slewing ring should install the soft zone of the slewing ring accordingly. Since a soft zone will inevitably appear in the slewing ring, the user of the slewing bearing must install the soft zone reasonably to prolong the service life of the slewing ring. Generally, the soft zone should be installed at the minimum loading position.

Generally, the upper ring soft zone of rotating equipment is installed at a position perpendicular to the projection line of the pitch rotating surface. For example, the upper ring soft zone of a loader or stacked rotating equipment should be installed perpendicular to the pitch rotating surface. The center line of the cantilever cuts through the center of rotation, that is, the 90 degree position where the left or right side of the cantilever faces the center of rotation. In the usual mechanical design, the soft zone will not bear the greatest force. The installation position of the lower ring soft zone of the rotating equipment should be determined according to the center of gravity and the range of the rotation angle of the equipment. If the left and right rotation angle is 100 degrees, the maximum center of gravity position above the rotating part is in the front. It is recommended to install the lower ring soft zone at the rear, that is, at a position of 180 degrees. If the changing position of the center of gravity above the rotation is equal in the front and rear positions, the angular position of the lower ring soft zone can be installed arbitrarily.

Invitation to Visit Xuzhou Wanda Slewing Bearing Co., Ltd. at Bauma 2025

Anti-rust advice for stocked slewing bearings of XZWD company

Xuzhou Wanda slewing bearing successfully delivered a 5 meters slewing bearing for floating crane

The Surface Treatment of Slewing bearings: Painting, Zinc spraying, Zinc Plating, Nickel Plating.

Home | About Us | Products | News | Application | Support | Contact Us