Views: 60 Author: Site Editor Publish Time: 2023-02-28 Origin: Site

1. Unpack the package before installing the slewing bearing and confirm whether it is consistent with the selected model according to the certificate of conformity and the label information on the slewing bearing: carefully check the appearance and check whether the slewing bearing has bumps or major damage during transportation; manually rotate For the slewing bearing, check whether the rotation of the slewing bearing is flexible; check whether the installation base is flat, the installation base should be a machined surface, and the installation surface should be flat and free of burrs.

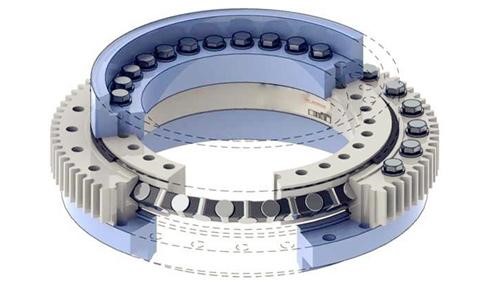

2. When installing the slewing bearing, hoist the slewing bearing horizontally on the installation foundation platform, check the position of the soft belt (general mark S), and place the soft belt and the blocked position in the non-load area or light load area. Use a feeler gauge to check whether there is a gap between the plane of the slewing support and the plane of the installation foundation. If there is a large gap, it proves that the flatness of the installation foundation is not good. If conditions permit, the installation foundation should be reprocessed. The method of skinning eliminates the gap, which can prevent the slewing bearing from being pulled and deformed after the bolts are tightened, which will affect the slewing performance and life of the slewing bearing. The installation bolts should be symmetrical and continuous in the direction of 180°, and then check again to ensure that all the bolts on the circumference are as required.

Find the torque to tighten. It is not recommended to use non-standard bolts. Old bolts and open elastic washers cannot be used.

3.If the slewing bearing with teeth is installed, it is important to adjust the backlash of the teeth. The correct backlash is very important. Find the position of the tooth height point (green paint or blue paint on the top of the tooth), and use a cold ruler to adjust the slewing bearing and small Gear backlash. Generally, the backlash value is adjusted to (003-004) times the horizontal number. After adjusting the tooth side, actively rotate the slewing bearing for at least one circle to verify that the teeth mesh without stagnation, and then tighten the mounting bolts symmetrically and continuously in the direction of 180°, and then check Make sure that all the bolts on the circumference are tightened according to the required torque.

4. After all the installation bolts are tightened, the sundries between the large and small gears, on and around the slewing bearing should be removed in time, and the adjacent parts should be checked to ensure that the rotation of the slewing bearing will not interfere with it. Then, grease the gears and turn on the equipment Jog and rotate slowly a few times, and carefully check whether the slewing ring is running smoothly, whether the gears are meshing normally, whether there are abnormal noises and stagnation.

The quality of the production and processing of the slewing bearing is very important, and the correct installation and use are equally important. Only the correct installation and use of the slewing bearing and timely maintenance can it run smoothly on various mechanical equipment and increase the service life of the slewing bearing.

Invitation to Visit Xuzhou Wanda Slewing Bearing Co., Ltd. at Bauma 2025

Anti-rust advice for stocked slewing bearings of XZWD company

Xuzhou Wanda slewing bearing successfully delivered a 5 meters slewing bearing for floating crane

The Surface Treatment of Slewing bearings: Painting, Zinc spraying, Zinc Plating, Nickel Plating.

Home | About Us | Products | News | Application | Support | Contact Us