Views: 35 Author: Site Editor Publish Time: 2021-07-10 Origin: Site

Slewing bearing technology improvement and performance improvement

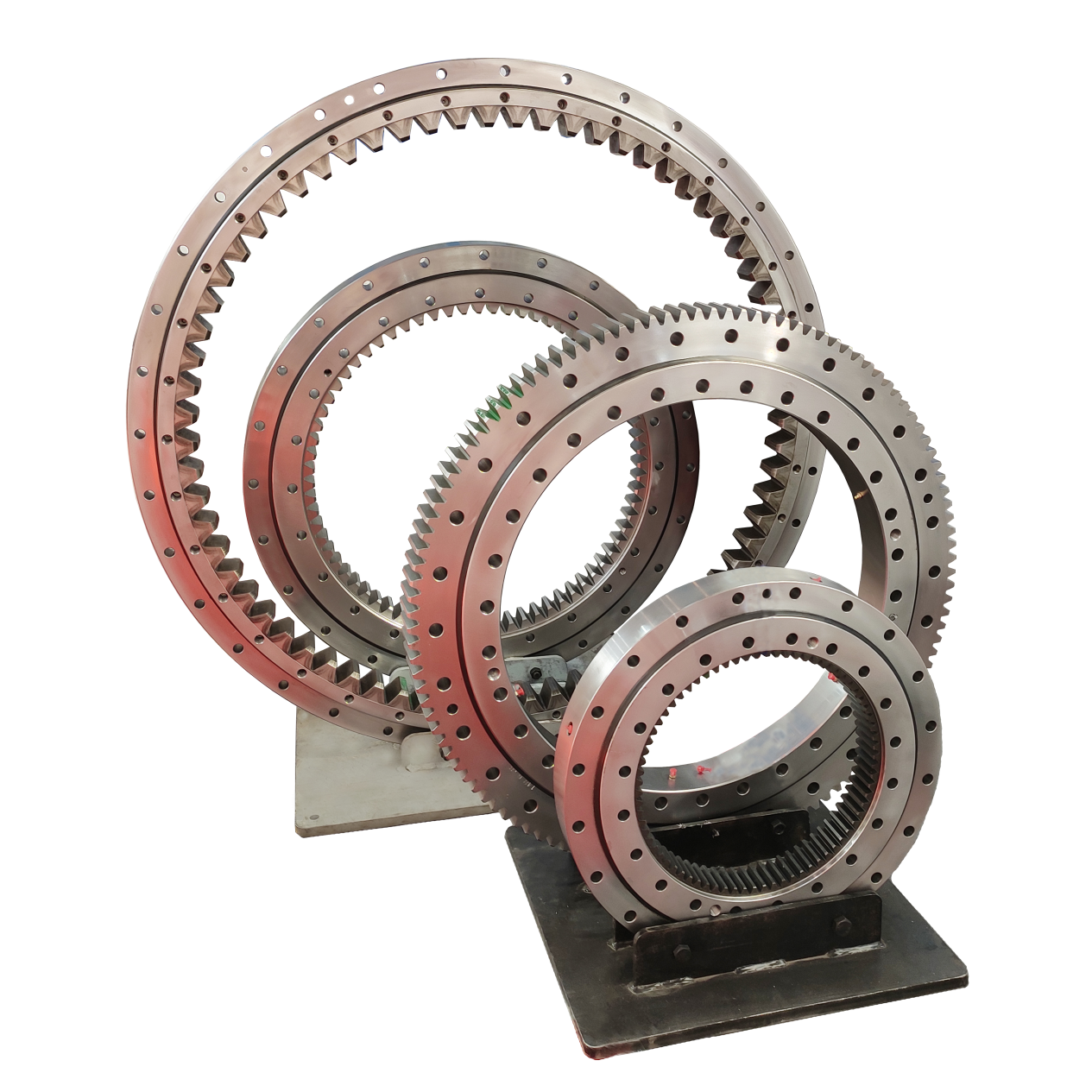

Slewing bearings occupies an important position in the application of equipment in many industries. In order to better assist the operation of equipment, we can start from the improvement of production technology and performance improvement:

1.The quality of 50Mn steel must be improved, and the content of chemical composition and the level of non-metallic inclusions must be strictly controlled. This is one of the important measures to improve the quality of slewing bearings.

2.Due to the large machining allowance of the blank, larger cutting stress may be generated and quenching deformation may be increased. In order to improve accuracy and reduce deformation, it can be subjected to intermediate stress relief annealing after rough turning.

3.Improve the design of the slewing ring. The steel ball arc raceway has been widely adopted abroad (the steel ball diameter is 25mm). The structure is uniformly stressed, and the raceway has a brightness of 6, and it is directly polished after quenching, without grinding, which can prevent defects such as cracks in the raceway.

4.Large bearings(www.slew-bearing.com) not only require the raceway surface to be wear-resistant, but also have a certain strength. In addition to quenching and tempering, the depth of the hardened layer must be increased as much as possible. The actual test proves that by increasing the unit heating power of the intermediate frequency quenching (from 1.6Kw/mm2 to 2.4Kw/mm2) and reducing the heating speed, the hardened layer can be increased to 3-4mm, which can increase the strength of the raceway.

5.The processing quality of the slewing bearing itself is greatly affected by the manufacturing accuracy, the axial clearance and the heat treatment state. The factor that is easy to ignore here is the influence of the heat treatment state. Obviously, in order to prevent cracks and depressions on the surface of the raceway, the raceway surface must have sufficient hardness, as well as sufficient hardened layer depth and core hardness. According to foreign data, the depth of the hardened layer of the raceway should be thickened as the rolling elements increase, to a depth of more than 6mm, and the hardness of the core should also be higher, so that the raceway will have a higher ability to resist crushing. Therefore, the lack of depth of the hardened layer on the surface of the slewing ring raceway and the low hardness of the core are also one of the reasons for its damage. The key to improving the manufacturing accuracy of the slewing ring lies in the heat treatment process. It can reduce the intermediate frequency quenching speed, try to obtain a larger surface hardness and hardening depth, and prevent quenching cracks on the surface of the raceway.

Invitation to Visit Xuzhou Wanda Slewing Bearing Co., Ltd. at Bauma 2025

Anti-rust advice for stocked slewing bearings of XZWD company

Xuzhou Wanda slewing bearing successfully delivered a 5 meters slewing bearing for floating crane

The Surface Treatment of Slewing bearings: Painting, Zinc spraying, Zinc Plating, Nickel Plating.

Home | About Us | Products | News | Application | Support | Contact Us