Publish Time: 2018-07-02 Origin: Site

A slewing bearing or slewing ring is a new type of mechanical component, which consists of inner and outer ring, rolling body and so on. The slewing bearing is a large bearing which can bear the comprehensive load. It can bear large axial, radial load and overturning moment at the same time.

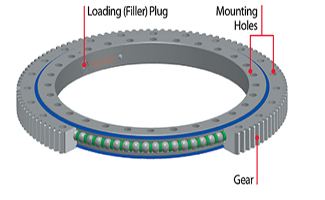

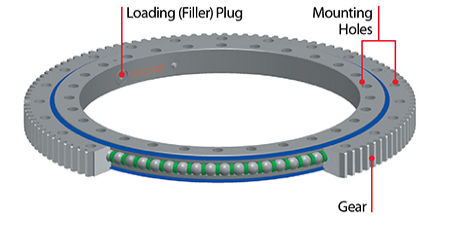

From the slewing bearing left and right (upper part): 1. outer ring (toothed or toothless) 2. sealing belt 3. rolling body (ball or roller) 4. oil hole from left and right (lower part): 1. plug 2. plug pin 3. inner ring (toothed or toothless) 4. isolating block or cage 5. installation hole (threaded hole or light hole)

Slewing bearings often use two rows of rolling elements. They often use three race elements, such as an inner ring and two outer ring "halves" that clamp together axially.Slewing bearings are often made with gear teeth integral with the inner or outer race, used to drive the platform relative to the base.

are a great solution for simplifying drive systems, especially when space is limited. Designers should carefully consider static strength, fatigue, resistance to pitting, and gear/pinion interfaces when choosing a bearing for any application, and should include backlash room in their designs.

Single row geared slewing bearings are mainly used in rotary conveyors, welding machines, small and medium sized cranes and excavators. Double row geared slewing bearings are mainly used in tower crane, truck crane and other loading and unloading machinery.The three row geared slewing bearing is mainly used in bucket wheel excavator, wheel crane, ship crane, port crane, steel water transport platform and large tonnage truck crane and so on.

Anti-rust advice for stocked slewing bearings of XZWD company

Xuzhou Wanda slewing bearing successfully delivered a 5 meters slewing bearing for floating crane

The Surface Treatment of Slewing bearings: Painting, Zinc spraying, Zinc Plating, Nickel Plating.

Slewing bearing with external gear vs slewing bearing with internal gear