Views: 20 Author: Yingying Zhou Publish Time: 2018-08-10 Origin: Site

Review the following application information section before proceeding with slewing bearing selection. The application information section is a guide for selecting a bearing used in a normal application as defined on.Determine the maximum bearing loads. These loads must include all dynamic and static loads imposed on the bearing. The loads in turn must be transposed to loads acting at the bearing’s center. All applied forces to the bearing and gear. Not only the rated and working loads but also those that may occur when equipment is at rest, such as that due to wind for larger structures.Loads imposed during overload or testing situations.Loads imposed during assembly or disassembly.

Weights of all members of the structure which are supported by the bearing All possible combinations of maximum loads. A crane, for example, usually has a number of conditions of load versus working radii, both during use and at time of overload testing.

If an integral gear is desired, determine the required gear capacity. As with the bearing loads, consideration must be given to all conditions that would generate potential gear loads; some examples include those while working, static, on incline, and overload testing. One must also consider the duty cycle at each of these conditions for assistance in determining bearing rotational resistance.

In a word,the size of the slewing ring required is dependent on the demands made on its:

Static and dynamic load carrying capacity,Life ,Operational reliability

Static reference load Fa 'and M' is calculated:

Single row ball Slewing ring bearing (turntable bearing) Selection calculation method:

Single-row four point contact ball slewing ring bearing selection calculation respectively by 45 ° and 60 ° angle of two cases.

I, a = 45 ° II, a = 60 °

Fa '= (1.225 * Fa +2.676 * Fr) * fs Fa' = (Fa +5.046 * Fr) * fs

M '= 1.225 * M * fs M' = M * fs

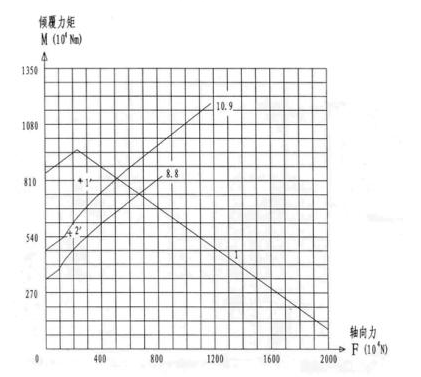

Then find the above two curves, one of which the following can be in the curve.

l line static bearing capacity curves

8.8, 10.9 for the bolt load curve

1'-static load point

2'-bolt load point

A 'point and then static bearing raceway below the curve 1, so to meet the requirements

2 'at 10.9 points below the bolt load curve, so select the 0.9 bolts meet the requirements.

Home | About Us | Products | News | Application | Support | Contact Us