Slewing drives function with standard worm technology, in which the worm on the horizontal shaft acts as the driver for the gear. The rotation of the horizontal screw turns a gear about an axis perpendicular to the screw axis. This combination reduces the speed of the driven member and also multiplies its torque; increasing it proportionally as the speed decreases.The speed ratio of shafts depends upon the relation of the number of threads on the worm to the number of teeth in the worm wheel or gear.

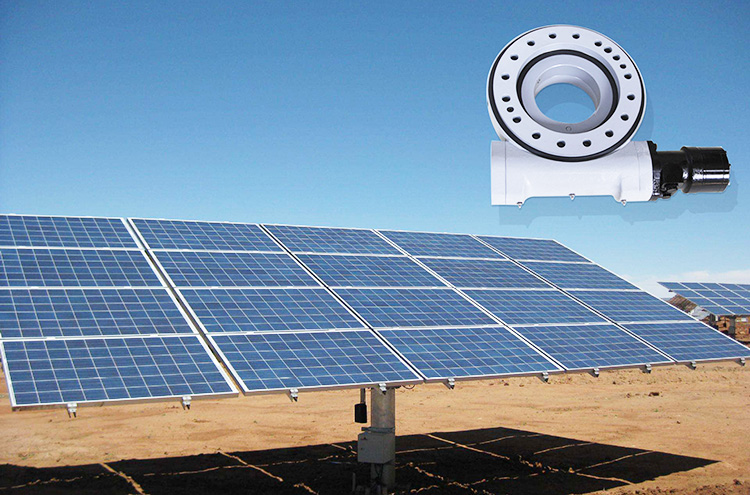

These are specifically used in solar tracking systems where horizontal axis tracking is required. The precise rotation enables the mechanism to track.

Solar power plants require robust drive systems with high accuracy, efficiency and virtually maintenance-free long-term operation showing a high degree of reliability.

Only components specially designed for outdoor use canmeet the requirements. Worm gear units are ideally suited for the azimuth adjustment of a tracker, since they can be used for virtually transmission ratios and very slow movements.

By target-oriented selection of defined materials, required parameters

such as perfect wear behaviour, high fatigue strength and long-term corrosion protection are achieved and implemented.

Because of their multiple uses, slewing drives come in a variety of model sizes, performance ranges and mounting characteristics. The drives are well suited for applications that require both load holding and rotational torque from the same gear box. They can also be made with dual axes of rotation, (turning axes at the same time) or with dual drives on the same axis, (two worm threads driving the same ring gear in one axis)

There are many applications in which the slewing drive can be utilized, primarily because it is perfect for applications that require both load-holding power and rotational torque strength.

Such types of Slew drive are perfect for applications that require both load holding and rotational torque from the same gear box. The drives come with an hourglass worm technology, which increase the efficiency of the drives. The difference between normal and hourglass technology is that, in a conventional worm gearing system, only one tooth of the gear is in contact with the worm shaft,

The slew drive comes in two types: single row ball and double row ball. These are selected depending on the load coming on the drive. Higher loads generally need double row slew bearing.

The drive is manufactured using the latest technology which incorporates hourglass mechanism. Also, because of this, the tooth contact form has greater torque holding capacity than the normal drive. This enables bigger panels to be mounted, thus reducing the installation costs.

The drives come with an IP65 rated protection system, which protects the drive from environmental conditions as well as dirt, sand, dust and even water. The drive is designed in such a way that huge loads can be carried in spite of the compact form factor. The gears used in the assembly are hardened and ground, so that they provide maximum durability and longer life.

Post-maintenance/inspection

Lubricant analysis

Check of the bolts

Home | About Us | Products | News | Application | Support | Contact Us