Views: 44 Author: Hebe Publish Time: 2018-11-08 Origin: Site

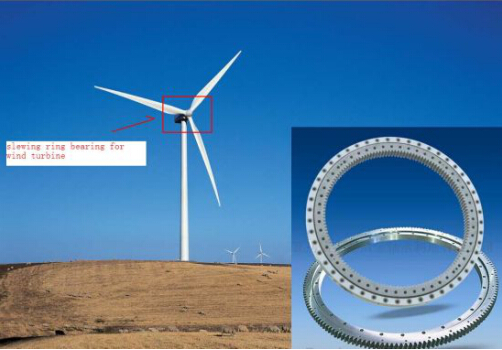

Wind power and other alternative energy forms continue to grow in usage. Companies are increasingly using wind to power manufacturing plants and reduce the need for nonrenewable energy sources. Slewing ring bearings play a necessary role in the production of wind power. But when the slewing ring bearings used in wind turbines don’t do their job, the cost of doing business can rise drastically and quickly.

Slewing ring application in wind power specifically require a combination of even balance, efficient design and durability to stand up to the tests of time. That means you need to get the right part for the job at the very beginning. Talking to a slewing ring bearing engineer prior to purchasing can be the first step in a winning project.

Wind turbines must be aligned to the wind conditions. The tower and the rotor blades are adjusted so that they make optimal use of the wind conditions and are not subject to excessive loads that could cause damage. Slewing rings with an outside diameter of up to 4,100 millimeters for wind tracking. Due to their design, they can transmit radial and axial forces and tilting moments. They are designed as single row or double row four point contact bearings without gear teeth or with internal and/or external gear teeth. Their reliable function is a significant prerequisite for cost-effective operation of wind turbines.

Wind turbines must be aligned to the wind conditions. The tower and the rotor blades are adjusted so that they make optimal use of the wind conditions and are not subject to excessive loads that could cause damage. Slewing rings with an outside diameter of up to 4,100 millimeters for wind tracking. Due to their design, they can transmit radial and axial forces and tilting moments. They are designed as single row or double row four point contact bearings without gear teeth or with internal and/or external gear teeth. Their reliable function is a significant prerequisite for cost-effective operation of wind turbines.

Generally, there are two types of bearings used in wind power: slewing ring bearings and spherical roller bearings. Slewing ring bearings are used in the pitch and yaw locations within a wind turbine, and they are used to keep the blades rotating smoothly.

Getting a product that is not precisely constructed can cause an uneven distribution of weight in a wind turbine and total system failure. This is both dangerous and extremely costly. Aside from normal wear and tear that occurs naturally over time, slewing ring bearings don’t usually have any problems as long as they’re properly maintained.

Home | About Us | Products | News | Application | Support | Contact Us