| Availability: | |

|---|---|

| Quantity: | |

A slewing bearing or slew[ing] ring is a rotationalrolling-element bearing or plain bearing that typically supports a heavy but slow-turning or slow-oscillating load, often a horizontal platform such as a conventional crane, a swing yarder, or the wind-facing platform of a horizontal-axis windmill. (To "slew" means to turn without change of place.)

Compared to other rolling-element bearings, slewing bearings are thin in section and are often made in diameters of a metre or more; the slewing bearings on the Falkirk Wheel are 4 metres diameter and fit over a 3.5 metre axle. Slewing bearings resemble oversize aircraft control surface bearings.

Slewing bearings often use two rows of rolling elements. They often use three race elements, such as an inner ring and two outer ring "halves" that clamp together axially.

Slewing bearings are often made with gear teeth integral with the inner or outer race, used to drive the platform relative to the base.

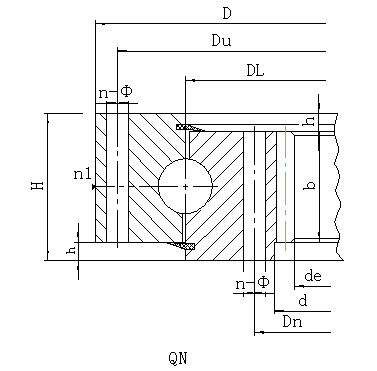

NO | Model | Mounting dimensions (mm) | Structural (mm) | Gear data | |||||||||||||

Internal gear | H | Du | Dn | n | Through hole A | Threaded hole B/C/D | n1Oil cup qty | h | B | m | x=+0.5 | ||||||

de | Gear qty z | Weight | |||||||||||||||

D | d | φ | d1 | T | |||||||||||||

mm | mm | mm | mm | kg | |||||||||||||

1 | QN.315.20 | 408 | 224 | 60 | 370 | 260 | 10 | 17 | M16 | 24 | 2 | 10 | 40 | 3 | 207 | 70 | 34 |

4 | 200 | 51 | 35 | ||||||||||||||

2 | QN.355.20 | 448 | 264 | 60 | 410 | 300 | 10 | 17 | M16 | 24 | 2 | 10 | 40 | 3 | 246 | 84 | 39 |

4 | 240 | 61 | 40 | ||||||||||||||

3 | QN.400.20 | 493 | 310 | 60 | 455 | 345 | 12 | 17 | M16 | 24 | 2 | 10 | 40 | 4 | 288 | 73 | 44 |

5 | 280 | 57 | 46 | ||||||||||||||

4 | QN.450.20 | 543 | 360 | 60 | 505 | 395 | 12 | 17 | M16 | 24 | 2 | 10 | 40 | 4 | 336 | 85 | 50 |

5 | 330 | 67 | 52 | ||||||||||||||

5 | QN.500.20 | 593 | 410 | 60 | 555 | 445 | 14 | 17 | M16 | 24 | 2 | 10 | 40 | 5 | 385 | 78 | 55 |

6 | 378 | 64 | 57 | ||||||||||||||

6 | QN.560.20 | 656 | 468 | 70 | 618 | 502 | 14 | 17 | M16 | 30 | 2 | 10 | 50 | 4 | 440 | 111 | 76 |

5 | 435 | 88 | 77 | ||||||||||||||

7 | QN.630.20 | 726 | 538 | 70 | 688 | 572 | 16 | 17 | M16 | 30 | 2 | 10 | 50 | 4 | 512 | 129 | 84 |

5 | 505 | 102 | 86 | ||||||||||||||

8 | QN.710.20 | 806 | 618 | 70 | 768 | 652 | 18 | 17 | M16 | 30 | 2 | 10 | 50 | 5 | 585 | 118 | 97 |

6 | 582 | 98 | 97 | ||||||||||||||

9 | QN.800.20 | 896 | 708 | 70 | 858 | 742 | 20 | 17 | M16 | 30 | 2 | 10 | 50 | 6 | 672 | 113 | 110 |

8 | 664 | 84 | 111 | ||||||||||||||

10 | QN.800.25 | 908 | 694 | 78 | 864 | 736 | 18 | 22 | M20 | 36 | 2 | 10 | 58 | 6 | 654 | 110 | 142 |

8 | 648 | 82 | 142 | ||||||||||||||

11 | QN.900.25 | 1008 | 794 | 78 | 964 | 836 | 20 | 22 | M20 | 36 | 2 | 10 | 58 | 8 | 744 | 94 | 163 |

10 | 740 | 75 | 162 | ||||||||||||||

12 | QN.1000.25 | 1108 | 894 | 78 | 1064 | 936 | 24 | 22 | M20 | 36 | 2 | 10 | 58 | 8 | 848 | 107 | 178 |

QN.1000.25A | 10 | 840 | 85 | 179 | |||||||||||||

13 | QN.1000.32 | 1124 | 880 | 90 | 1074 | 926 | 24 | 24 | M22 | 40 | 2 | 10 | 70 | 8 | 832 | 105 | 230 |

10 | 830 | 84 | 227 | ||||||||||||||

14 | QN.1120.32 | 1244 | 1000 | 90 | 1194 | 1046 | 28 | 24 | M22 | 40 | 4 | 10 | 70 | 10 | 940 | 95 | 263 |

12 | 936 | 79 | 262 | ||||||||||||||

15 | QN.1250.32 | 1374 | 1130 | 90 | 1324 | 1176 | 32 | 24 | M22 | 40 | 4 | 10 | 70 | 10 | 1070 | 108 | 294 |

QN.1250.32A | 12 | 1068 | 90 | 290 | |||||||||||||

16 | QN.1400.32 | 1524 | 1280 | 90 | 1474 | 1326 | 36 | 24 | M22 | 40 | 4 | 10 | 70 | 12 | 1212 | 102 | 333 |

QN.1400.32A | 14 | 1204 | 87 | 336 | |||||||||||||

17 | QN.1250.40 | 1394 | 1110 | 102 | 1336 | 1164 | 32 | 26 | M24 | 45 | 4 | 12 | 80 | 10 | 1050 | 106 | 388 |

12 | 1044 | 88 | 388 | ||||||||||||||

18 | QN.1400.40 | 1544 | 1260 | 102 | 1486 | 1314 | 36 | 26 | M24 | 45 | 4 | 12 | 80 | 12 | 1188 | 100 | 444 |

14 | 1190 | 86 | 434 | ||||||||||||||

19 | QN.1600.40 | 1744 | 1460 | 102 | 1686 | 1514 | 40 | 26 | M24 | 45 | 4 | 12 | 80 | 12 | 1392 | 117 | 509 |

QN.1600.40A | 14 | 1386 | 100 | 511 | |||||||||||||

20 | QN.1800.40 | 1944 | 1660 | 102 | 1886 | 1714 | 44 | 26 | M24 | 45 | 4 | 12 | 80 | 14 | 1582 | 114 | 576 |

QN.1800.40A | 16 | 1568 | 99 | 591 | |||||||||||||

21 | QN.1600.50 | 1766 | 1438 | 124 | 1704 | 1496 | 40 | 30 | M27 | 50 | 4 | 12 | 100 | 12 | 1368 | 115 | 714 |

14 | 1358 | 98 | 723 | ||||||||||||||

22 | QN.1800.50 | 1966 | 1638 | 124 | 1904 | 1696 | 44 | 30 | M27 | 50 | 4 | 12 | 100 | 14 | 1568 | 113 | 794 |

16 | 1552 | 98 | 818 | ||||||||||||||

23 | QN.2000.50 | 2166 | 1842 | 124 | 2104 | 1896 | 48 | 30 | M27 | 50 | 6 | 12 | 100 | 16 | 1760 | 111 | 891 |

QN.2000.50A | 18 | 1746 | 98 | 913 | |||||||||||||

24 | QN.2240.50 | 2406 | 2078 | 124 | 2344 | 2136 | 54 | 30 | M27 | 50 | 6 | 12 | 100 | 16 | 1984 | 125 | 1044 |

QN.2240.50A | 18 | 1980 | 111 | 1041 | |||||||||||||

25 | QN.2500.50 | 2666 | 2342 | 124 | 2604 | 2396 | 60 | 30 | M27 | 50 | 6 | 12 | 100 | 18 | 2250 | 126 | 1132 |

QN.2500.50A | 20 | 2240 | 113 | 1148 | |||||||||||||

26 | QN.2500.60 | 2696 | 2308 | 150 | 2626 | 2374 | 60 | 33 | M30 | 56 | 6 | 14 | 122 | 18 | 2214 | 124 | 1621 |

QN.2500.60A | 20 | 2200 | 111 | 1654 | |||||||||||||

Note:

1. N1 is the numbers of lubricating holes. Oil cup M10×1JB/T7940.1~JB/T7940.

2. The Oil nipple's location can be change according to the user's application.

3. n-φ can change to tapped hole, the diameter of tapped hole is M, and depth is 2M.

4. The tangential tooth force in the form is the max tooth force; the nominal tangential tooth force is 1/2 of the max one.

5. "K" is addendum reduction coefficient.

Our advantages:

Germany technology and made-in-China with good quality and competitive price;

Rich experience in OEM and ODM;

stable and fast delivery;

prompt and responsible after-sales service;

Certified by ISO9001:2008, SGS, CCS and BV.

Packaging&shipping

1.Filling with rust-proof oil

2.packing with protective layers

3.Fixed in the plywood

4.Packaging terms:Plywood case/ Pallet/Steel frame

FAQ

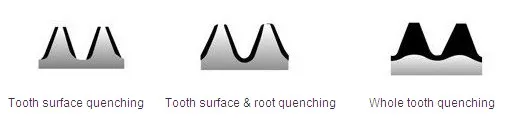

1.Slewing Bearing Heat Treatment

Xuzhou Wanda company bearings are in the majority of cases supplied with spur tooth. Stub teeth also is ok.There are two kinds of tooth hardening. They are normalizing and tempering, According to the different applications, there are two ways of quenching. They're whole tooth quenching and single-tooth quenching. Single-tooth quenching can be divided into tooth surface & root quenching and tooth surface quenching.

2. Protection Against Corrosion

We make Protection Against Corrosion on surface of bearing,and make couple of packing paper.

3.Customize.

Yes,we have professional technical terms.

4.Warranty:

General 1 year.

5. Reliable reputation.

Wanda Slewing bearing/Slewing drive delivers custom-engineered solutions to customers in 34 countries.

A slewing bearing or slew[ing] ring is a rotationalrolling-element bearing or plain bearing that typically supports a heavy but slow-turning or slow-oscillating load, often a horizontal platform such as a conventional crane, a swing yarder, or the wind-facing platform of a horizontal-axis windmill. (To "slew" means to turn without change of place.)

Compared to other rolling-element bearings, slewing bearings are thin in section and are often made in diameters of a metre or more; the slewing bearings on the Falkirk Wheel are 4 metres diameter and fit over a 3.5 metre axle. Slewing bearings resemble oversize aircraft control surface bearings.

Slewing bearings often use two rows of rolling elements. They often use three race elements, such as an inner ring and two outer ring "halves" that clamp together axially.

Slewing bearings are often made with gear teeth integral with the inner or outer race, used to drive the platform relative to the base.

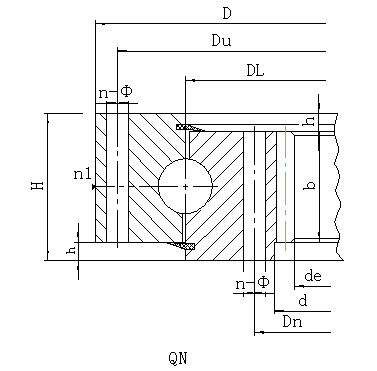

NO | Model | Mounting dimensions (mm) | Structural (mm) | Gear data | |||||||||||||

Internal gear | H | Du | Dn | n | Through hole A | Threaded hole B/C/D | n1Oil cup qty | h | B | m | x=+0.5 | ||||||

de | Gear qty z | Weight | |||||||||||||||

D | d | φ | d1 | T | |||||||||||||

mm | mm | mm | mm | kg | |||||||||||||

1 | QN.315.20 | 408 | 224 | 60 | 370 | 260 | 10 | 17 | M16 | 24 | 2 | 10 | 40 | 3 | 207 | 70 | 34 |

4 | 200 | 51 | 35 | ||||||||||||||

2 | QN.355.20 | 448 | 264 | 60 | 410 | 300 | 10 | 17 | M16 | 24 | 2 | 10 | 40 | 3 | 246 | 84 | 39 |

4 | 240 | 61 | 40 | ||||||||||||||

3 | QN.400.20 | 493 | 310 | 60 | 455 | 345 | 12 | 17 | M16 | 24 | 2 | 10 | 40 | 4 | 288 | 73 | 44 |

5 | 280 | 57 | 46 | ||||||||||||||

4 | QN.450.20 | 543 | 360 | 60 | 505 | 395 | 12 | 17 | M16 | 24 | 2 | 10 | 40 | 4 | 336 | 85 | 50 |

5 | 330 | 67 | 52 | ||||||||||||||

5 | QN.500.20 | 593 | 410 | 60 | 555 | 445 | 14 | 17 | M16 | 24 | 2 | 10 | 40 | 5 | 385 | 78 | 55 |

6 | 378 | 64 | 57 | ||||||||||||||

6 | QN.560.20 | 656 | 468 | 70 | 618 | 502 | 14 | 17 | M16 | 30 | 2 | 10 | 50 | 4 | 440 | 111 | 76 |

5 | 435 | 88 | 77 | ||||||||||||||

7 | QN.630.20 | 726 | 538 | 70 | 688 | 572 | 16 | 17 | M16 | 30 | 2 | 10 | 50 | 4 | 512 | 129 | 84 |

5 | 505 | 102 | 86 | ||||||||||||||

8 | QN.710.20 | 806 | 618 | 70 | 768 | 652 | 18 | 17 | M16 | 30 | 2 | 10 | 50 | 5 | 585 | 118 | 97 |

6 | 582 | 98 | 97 | ||||||||||||||

9 | QN.800.20 | 896 | 708 | 70 | 858 | 742 | 20 | 17 | M16 | 30 | 2 | 10 | 50 | 6 | 672 | 113 | 110 |

8 | 664 | 84 | 111 | ||||||||||||||

10 | QN.800.25 | 908 | 694 | 78 | 864 | 736 | 18 | 22 | M20 | 36 | 2 | 10 | 58 | 6 | 654 | 110 | 142 |

8 | 648 | 82 | 142 | ||||||||||||||

11 | QN.900.25 | 1008 | 794 | 78 | 964 | 836 | 20 | 22 | M20 | 36 | 2 | 10 | 58 | 8 | 744 | 94 | 163 |

10 | 740 | 75 | 162 | ||||||||||||||

12 | QN.1000.25 | 1108 | 894 | 78 | 1064 | 936 | 24 | 22 | M20 | 36 | 2 | 10 | 58 | 8 | 848 | 107 | 178 |

QN.1000.25A | 10 | 840 | 85 | 179 | |||||||||||||

13 | QN.1000.32 | 1124 | 880 | 90 | 1074 | 926 | 24 | 24 | M22 | 40 | 2 | 10 | 70 | 8 | 832 | 105 | 230 |

10 | 830 | 84 | 227 | ||||||||||||||

14 | QN.1120.32 | 1244 | 1000 | 90 | 1194 | 1046 | 28 | 24 | M22 | 40 | 4 | 10 | 70 | 10 | 940 | 95 | 263 |

12 | 936 | 79 | 262 | ||||||||||||||

15 | QN.1250.32 | 1374 | 1130 | 90 | 1324 | 1176 | 32 | 24 | M22 | 40 | 4 | 10 | 70 | 10 | 1070 | 108 | 294 |

QN.1250.32A | 12 | 1068 | 90 | 290 | |||||||||||||

16 | QN.1400.32 | 1524 | 1280 | 90 | 1474 | 1326 | 36 | 24 | M22 | 40 | 4 | 10 | 70 | 12 | 1212 | 102 | 333 |

QN.1400.32A | 14 | 1204 | 87 | 336 | |||||||||||||

17 | QN.1250.40 | 1394 | 1110 | 102 | 1336 | 1164 | 32 | 26 | M24 | 45 | 4 | 12 | 80 | 10 | 1050 | 106 | 388 |

12 | 1044 | 88 | 388 | ||||||||||||||

18 | QN.1400.40 | 1544 | 1260 | 102 | 1486 | 1314 | 36 | 26 | M24 | 45 | 4 | 12 | 80 | 12 | 1188 | 100 | 444 |

14 | 1190 | 86 | 434 | ||||||||||||||

19 | QN.1600.40 | 1744 | 1460 | 102 | 1686 | 1514 | 40 | 26 | M24 | 45 | 4 | 12 | 80 | 12 | 1392 | 117 | 509 |

QN.1600.40A | 14 | 1386 | 100 | 511 | |||||||||||||

20 | QN.1800.40 | 1944 | 1660 | 102 | 1886 | 1714 | 44 | 26 | M24 | 45 | 4 | 12 | 80 | 14 | 1582 | 114 | 576 |

QN.1800.40A | 16 | 1568 | 99 | 591 | |||||||||||||

21 | QN.1600.50 | 1766 | 1438 | 124 | 1704 | 1496 | 40 | 30 | M27 | 50 | 4 | 12 | 100 | 12 | 1368 | 115 | 714 |

14 | 1358 | 98 | 723 | ||||||||||||||

22 | QN.1800.50 | 1966 | 1638 | 124 | 1904 | 1696 | 44 | 30 | M27 | 50 | 4 | 12 | 100 | 14 | 1568 | 113 | 794 |

16 | 1552 | 98 | 818 | ||||||||||||||

23 | QN.2000.50 | 2166 | 1842 | 124 | 2104 | 1896 | 48 | 30 | M27 | 50 | 6 | 12 | 100 | 16 | 1760 | 111 | 891 |

QN.2000.50A | 18 | 1746 | 98 | 913 | |||||||||||||

24 | QN.2240.50 | 2406 | 2078 | 124 | 2344 | 2136 | 54 | 30 | M27 | 50 | 6 | 12 | 100 | 16 | 1984 | 125 | 1044 |

QN.2240.50A | 18 | 1980 | 111 | 1041 | |||||||||||||

25 | QN.2500.50 | 2666 | 2342 | 124 | 2604 | 2396 | 60 | 30 | M27 | 50 | 6 | 12 | 100 | 18 | 2250 | 126 | 1132 |

QN.2500.50A | 20 | 2240 | 113 | 1148 | |||||||||||||

26 | QN.2500.60 | 2696 | 2308 | 150 | 2626 | 2374 | 60 | 33 | M30 | 56 | 6 | 14 | 122 | 18 | 2214 | 124 | 1621 |

QN.2500.60A | 20 | 2200 | 111 | 1654 | |||||||||||||

Note:

1. N1 is the numbers of lubricating holes. Oil cup M10×1JB/T7940.1~JB/T7940.

2. The Oil nipple's location can be change according to the user's application.

3. n-φ can change to tapped hole, the diameter of tapped hole is M, and depth is 2M.

4. The tangential tooth force in the form is the max tooth force; the nominal tangential tooth force is 1/2 of the max one.

5. "K" is addendum reduction coefficient.

Our advantages:

Germany technology and made-in-China with good quality and competitive price;

Rich experience in OEM and ODM;

stable and fast delivery;

prompt and responsible after-sales service;

Certified by ISO9001:2008, SGS, CCS and BV.

Packaging&shipping

1.Filling with rust-proof oil

2.packing with protective layers

3.Fixed in the plywood

4.Packaging terms:Plywood case/ Pallet/Steel frame

FAQ

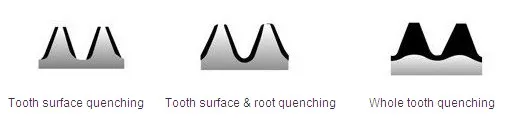

1.Slewing Bearing Heat Treatment

Xuzhou Wanda company bearings are in the majority of cases supplied with spur tooth. Stub teeth also is ok.There are two kinds of tooth hardening. They are normalizing and tempering, According to the different applications, there are two ways of quenching. They're whole tooth quenching and single-tooth quenching. Single-tooth quenching can be divided into tooth surface & root quenching and tooth surface quenching.

2. Protection Against Corrosion

We make Protection Against Corrosion on surface of bearing,and make couple of packing paper.

3.Customize.

Yes,we have professional technical terms.

4.Warranty:

General 1 year.

5. Reliable reputation.

Wanda Slewing bearing/Slewing drive delivers custom-engineered solutions to customers in 34 countries.

Home | About Us | Products | News | Application | Support | Contact Us