| Availability: | |

|---|---|

| Quantity: | |

WEA21

XZWD

Introduction:

By adopting slewing bearing as its core component, slewing drive can bear axial force, radial force and tilting moment simultaneously. Slewing drive is widely applied in modular trailers, all types of cranes, aerial working platform, solar tracking systems and wind power systems.

Electric and planetary gearboxes can be designed according to customer’s requirements. Slewing drive has the advantage for saving space in facilities, max load capacity in a compact design, extensive lifespan, and reduced maintenance costs.

Glossary

1) Tilting Moment Torque: Torque is the load multiplied by distance between the position of load and the center of slewing bearing. If the torque generated by load and distance is greater than the rated tilting moment torque, slewing drive will be overturned.

2) Radial load: Load vertical to the axis of slewing bearing

3) Axial load: Load parallel to the axis of slewing bearing

4) Holding torque: It is the reverse torque. When the drive is rotating reversely, and parts are not damaged,

5) The maximum torque achieved is called holding torque.

6) Self-locking: Only when loaded, the slewing drive is not able to reverse rotate and thus called self-locking.

--Customer can choose the motor according to our already designed slewing drive connect dimension.

--We can design the connect structure according to customer’s motor connect dimension.

--We can help to provide the whole parts with Hydraulic motor, DC motor, AC motor, Stepper or Servo motor.

- See more at: http://en.site33184760.tw.ldyjz.com/WEA14-pd6018425.html#sthash.qZSx1Xhz.dpufIntroduction:

By adopting slewing bearing as its core component, slewing drive can bear axial force, radial force and tilting moment simultaneously. Slewing drive is widely applied in modular trailers, all types of cranes, aerial working platform, solar tracking systems and wind power systems.

Electric and planetary gearboxes can be designed according to customer’s requirements. Slewing drive has the advantage for saving space in facilities, max load capacity in a compact design, extensive lifespan, and reduced maintenance costs.

Glossary

1) Tilting Moment Torque: Torque is the load multiplied by distance between the position of load and the center of slewing bearing. If the torque generated by load and distance is greater than the rated tilting moment torque, slewing drive will be overturned.

2) Radial load: Load vertical to the axis of slewing bearing

3) Axial load: Load parallel to the axis of slewing bearing

4) Holding torque: It is the reverse torque. When the drive is rotating reversely, and parts are not damaged,

5) The maximum torque achieved is called holding torque.

6) Self-locking: Only when loaded, the slewing drive is not able to reverse rotate and thus called self-locking.

--Customer can choose the motor according to our already designed slewing drive connect dimension.

--We can design the connect structure according to customer’s motor connect dimension.

--We can help to provide the whole parts with Hydraulic motor, DC motor, AC motor, Stepper or Servo motor.

- See more at: http://en.site33184760.tw.ldyjz.com/WEA14-pd6018425.html#sthash.qZSx1Xhz.dpuf

WEA series slewing drive,slew drive is a new series of slewing product, also named as slewing reducer. It is commonly composed of worm, slewing bearing, housing, motor adapter, end cap and other components. By adopting slewing bearing as its core component, slewing drive can bear axial force, radial force and tilting moment simultaneously. Comparing with SE series slewing drive, WEA series have the advantages of better protective performance, great transmission torque, better impact resistance and long working life.

WEA series slewing drive is widely applied in the relatively rotary parts of machinery and solar energy field. Solar tracking system Rotary chassis of aerial working machinery Truck crane Rock drill, drilling machine Grasping wood machine, code molding machine.

A self-propelled modular transporter or sometimes self-propelled modular trailer (SPMT) is a platform vehicle with a large array of wheels. SPMTs are used for transporting massive objects such as large bridge sections, oil refining equipment, motors and other objects that are too big or heavy for trucks.

To get drawing (pdf),please clik on Model.

To get drawing (pdf),please clik on Model.

Model | External Dimensions | Installation Dimensions | Mounting Hole Data | |||||||||||||

| Pdf.format | L1 | L2 | L3 | H2 | D0 | D2 | D3 | D4 | D5 | n1 | M1 | T1 | T2 | n2 | M2 | T3 |

mm | Inner Ring | Outer Ring | ||||||||||||||

424 | 330 | 180 | 108 | 360 | 175 | 146 | 222.5 | 270 | 15 | M16 | 30 | 62 | 16 | M16 | 30 | |

509 | 370 | 222.5 | 108 | 445 | 259 | 229 | 310 | 358 | 19 | M16 | 30 | 62 | 18 | M16 | 30 | |

544 | 380 | 240 | 108 | 480 | 295 | 265 | 342 | 390 | 23 | M16 | 30 | 56 | 18 | M16 | 30 | |

534 | 405 | 285 | 108 | 570 | 365.1 | 332 | 430 | 479.4 | 20 | M16 | 32 | 62 | 20 | M16 | 32 | |

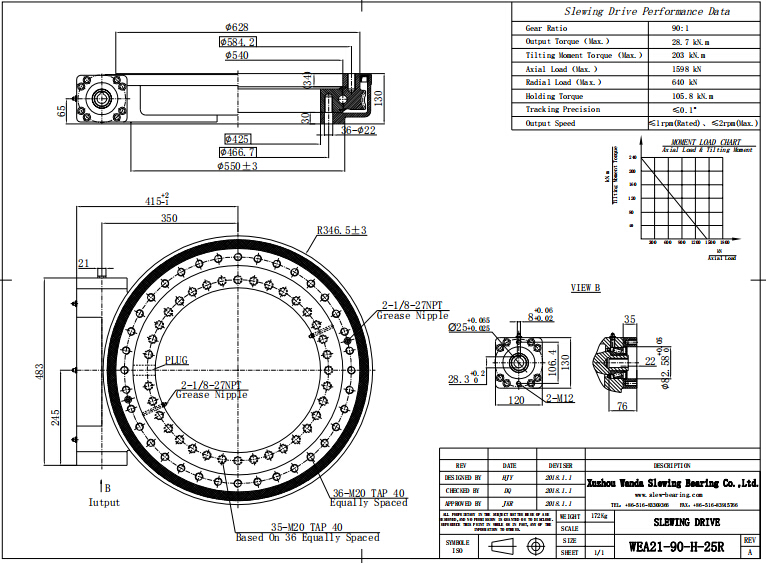

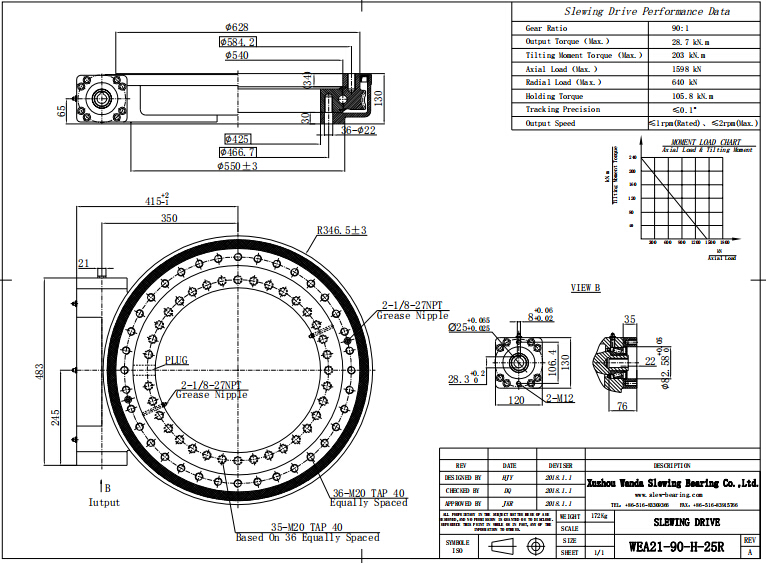

762 | 483 | 350 | 130 | 693 | 466.7 | 425 | 540 | 574.2 | 35 | M20 | 40 | 70 | 36 | M20 | 40 | |

861 | 513 | 399 | 130 | 793 | 565 | 525 | 630 | 675 | 35 | M20 | 40 | 70 | 36 | M20 | 40 | |

Model | Rated Ourput Torque kN.m | Tilting Moment Torque kN.m | Static Axial Load kN | Static Radial Load kN | Dynamic Axial Load kN | 56Dynamic Radial Load kN | Holding Torque kN.m | Gear Radio | Output Speed RPM | Self-locking Gears | Weight kg |

WEA9 | 8 | 33.9 | 550 | 205 | 130 | 110 | 38.7 | 62:1 | <3 | Yes | 53kg |

WEA12 | 9.5 | 54.3 | 725 | 270 | 180 | 140 | 43 | 79:1 | <3 | Yes | 66.8kg |

WEA14 | 10.8 | 67.8 | 920 | 343 | 220 | 190 | 48 | 86:1 | <3 | Yes | 75kg |

WEA17 | 12.96 | 135.6 | 1110 | 414 | 268 | 220 | 72.3 | 104:1 | <2 | Yes | 96kg |

WEA21 | 28.7 | 203 | 1595 | 596 | 340 | 270 | 105.8 | 90:1 | <1.5 | Yes | 172kg |

WEA25 | 34.2 | 310 | 1850 | 690 | 440 | 320 | 158.3 | 104:1 | <1.5 | Yes | 202kg |

Introduction:

By adopting slewing bearing as its core component, slewing drive can bear axial force, radial force and tilting moment simultaneously. Slewing drive is widely applied in modular trailers, all types of cranes, aerial working platform, solar tracking systems and wind power systems.

Electric and planetary gearboxes can be designed according to customer’s requirements. Slewing drive has the advantage for saving space in facilities, max load capacity in a compact design, extensive lifespan, and reduced maintenance costs.

Glossary

1) Tilting Moment Torque: Torque is the load multiplied by distance between the position of load and the center of slewing bearing. If the torque generated by load and distance is greater than the rated tilting moment torque, slewing drive will be overturned.

2) Radial load: Load vertical to the axis of slewing bearing

3) Axial load: Load parallel to the axis of slewing bearing

4) Holding torque: It is the reverse torque. When the drive is rotating reversely, and parts are not damaged,

5) The maximum torque achieved is called holding torque.

6) Self-locking: Only when loaded, the slewing drive is not able to reverse rotate and thus called self-locking.

--Customer can choose the motor according to our already designed slewing drive connect dimension.

--We can design the connect structure according to customer’s motor connect dimension.

--We can help to provide the whole parts with Hydraulic motor, DC motor, AC motor, Stepper or Servo motor.

- See more at: http://en.site33184760.tw.ldyjz.com/WEA14-pd6018425.html#sthash.qZSx1Xhz.dpufIntroduction:

By adopting slewing bearing as its core component, slewing drive can bear axial force, radial force and tilting moment simultaneously. Slewing drive is widely applied in modular trailers, all types of cranes, aerial working platform, solar tracking systems and wind power systems.

Electric and planetary gearboxes can be designed according to customer’s requirements. Slewing drive has the advantage for saving space in facilities, max load capacity in a compact design, extensive lifespan, and reduced maintenance costs.

Glossary

1) Tilting Moment Torque: Torque is the load multiplied by distance between the position of load and the center of slewing bearing. If the torque generated by load and distance is greater than the rated tilting moment torque, slewing drive will be overturned.

2) Radial load: Load vertical to the axis of slewing bearing

3) Axial load: Load parallel to the axis of slewing bearing

4) Holding torque: It is the reverse torque. When the drive is rotating reversely, and parts are not damaged,

5) The maximum torque achieved is called holding torque.

6) Self-locking: Only when loaded, the slewing drive is not able to reverse rotate and thus called self-locking.

--Customer can choose the motor according to our already designed slewing drive connect dimension.

--We can design the connect structure according to customer’s motor connect dimension.

--We can help to provide the whole parts with Hydraulic motor, DC motor, AC motor, Stepper or Servo motor.

- See more at: http://en.site33184760.tw.ldyjz.com/WEA14-pd6018425.html#sthash.qZSx1Xhz.dpuf

WEA series slewing drive,slew drive is a new series of slewing product, also named as slewing reducer. It is commonly composed of worm, slewing bearing, housing, motor adapter, end cap and other components. By adopting slewing bearing as its core component, slewing drive can bear axial force, radial force and tilting moment simultaneously. Comparing with SE series slewing drive, WEA series have the advantages of better protective performance, great transmission torque, better impact resistance and long working life.

WEA series slewing drive is widely applied in the relatively rotary parts of machinery and solar energy field. Solar tracking system Rotary chassis of aerial working machinery Truck crane Rock drill, drilling machine Grasping wood machine, code molding machine.

A self-propelled modular transporter or sometimes self-propelled modular trailer (SPMT) is a platform vehicle with a large array of wheels. SPMTs are used for transporting massive objects such as large bridge sections, oil refining equipment, motors and other objects that are too big or heavy for trucks.

To get drawing (pdf),please clik on Model.

To get drawing (pdf),please clik on Model.

Model | External Dimensions | Installation Dimensions | Mounting Hole Data | |||||||||||||

| Pdf.format | L1 | L2 | L3 | H2 | D0 | D2 | D3 | D4 | D5 | n1 | M1 | T1 | T2 | n2 | M2 | T3 |

mm | Inner Ring | Outer Ring | ||||||||||||||

424 | 330 | 180 | 108 | 360 | 175 | 146 | 222.5 | 270 | 15 | M16 | 30 | 62 | 16 | M16 | 30 | |

509 | 370 | 222.5 | 108 | 445 | 259 | 229 | 310 | 358 | 19 | M16 | 30 | 62 | 18 | M16 | 30 | |

544 | 380 | 240 | 108 | 480 | 295 | 265 | 342 | 390 | 23 | M16 | 30 | 56 | 18 | M16 | 30 | |

534 | 405 | 285 | 108 | 570 | 365.1 | 332 | 430 | 479.4 | 20 | M16 | 32 | 62 | 20 | M16 | 32 | |

762 | 483 | 350 | 130 | 693 | 466.7 | 425 | 540 | 574.2 | 35 | M20 | 40 | 70 | 36 | M20 | 40 | |

861 | 513 | 399 | 130 | 793 | 565 | 525 | 630 | 675 | 35 | M20 | 40 | 70 | 36 | M20 | 40 | |

Model | Rated Ourput Torque kN.m | Tilting Moment Torque kN.m | Static Axial Load kN | Static Radial Load kN | Dynamic Axial Load kN | 56Dynamic Radial Load kN | Holding Torque kN.m | Gear Radio | Output Speed RPM | Self-locking Gears | Weight kg |

WEA9 | 8 | 33.9 | 550 | 205 | 130 | 110 | 38.7 | 62:1 | <3 | Yes | 53kg |

WEA12 | 9.5 | 54.3 | 725 | 270 | 180 | 140 | 43 | 79:1 | <3 | Yes | 66.8kg |

WEA14 | 10.8 | 67.8 | 920 | 343 | 220 | 190 | 48 | 86:1 | <3 | Yes | 75kg |

WEA17 | 12.96 | 135.6 | 1110 | 414 | 268 | 220 | 72.3 | 104:1 | <2 | Yes | 96kg |

WEA21 | 28.7 | 203 | 1595 | 596 | 340 | 270 | 105.8 | 90:1 | <1.5 | Yes | 172kg |

WEA25 | 34.2 | 310 | 1850 | 690 | 440 | 320 | 158.3 | 104:1 | <1.5 | Yes | 202kg |

Home | About Us | Products | News | Application | Support | Contact Us