| Availability: | |

|---|---|

| Quantity: | |

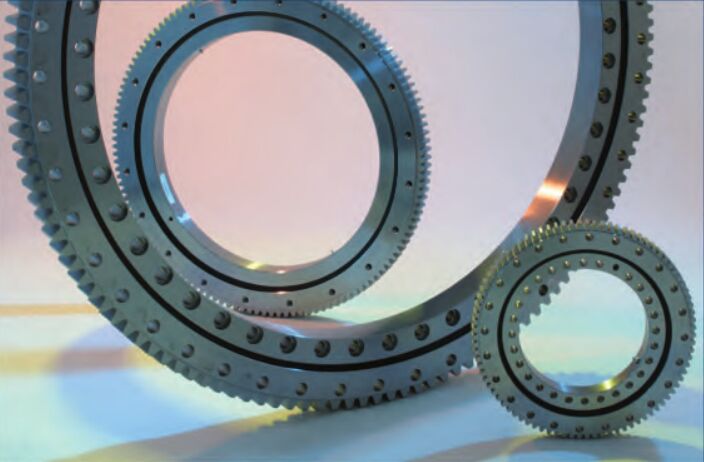

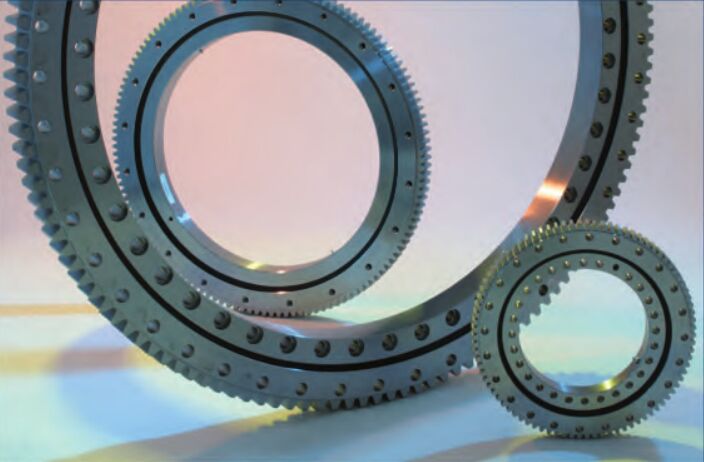

DWG713

XZWD

8482800000

single row ball slewing ring bearing must be installed in a horizontal position or on specially built incline cradles that support the ring structure appropriately. Any ovality so developed must be removed during installation.

usually have lifting holes for eye‐bolts to assist lifting in the inner and outer rings.Please check the weight of the ring to ensure slings and/or chains are of sufficient capacity! Shock loads, especially in the radial direction, must be avoided as this may damage the raceways.

If stacked on a pallet then care must be taken not to dislodge seal strips or grease fittings during

movement. Wooden or rubber spacers would be of benefit between each bearing. External gear

teeth (especially) should be protected from any impact damage.

As supplied slewing rings are generally packed for storage in a covered store and for a period not

exceeding 6 months. Light surface corrosion can usually be removed from exterior surfaces – and it is more important that the raceways are well greased and rust free. Standard commercial solvents can be used to degrease the slewing ring if necessary.

For slewing bearing environment, the mounting surface should be smooth and clean, removing all superfluous material such as paint residue, welding beads, burrs, etc.Care should be taken not to let the solvent infiltrate into the rotary support during cleaning. Do not use solvents that damage sealing materials.The mounting surface should be dry and free of lubricant before assembly.Measures should be taken to protect workers and the environment.

In extreme cases after long term storage bearings may need professionally reconditioning before

installation.When unwrapping, care must be taken not to cut and damage the integral seals.

The supporting surfaces must have a flat machined surface and be rigid enough to eliminate torsional buckling under load that would affect the smooth operation of the single row ball slewing ring bearing. The thickness of the supporting plates should be no less than that indicated below – which is offered as a rough approximation only.

single row ball slewing ring bearing must be installed in a horizontal position or on specially built incline cradles that support the ring structure appropriately. Any ovality so developed must be removed during installation.

usually have lifting holes for eye‐bolts to assist lifting in the inner and outer rings.Please check the weight of the ring to ensure slings and/or chains are of sufficient capacity! Shock loads, especially in the radial direction, must be avoided as this may damage the raceways.

If stacked on a pallet then care must be taken not to dislodge seal strips or grease fittings during

movement. Wooden or rubber spacers would be of benefit between each bearing. External gear

teeth (especially) should be protected from any impact damage.

As supplied slewing rings are generally packed for storage in a covered store and for a period not

exceeding 6 months. Light surface corrosion can usually be removed from exterior surfaces – and it is more important that the raceways are well greased and rust free. Standard commercial solvents can be used to degrease the slewing ring if necessary.

For slewing bearing environment, the mounting surface should be smooth and clean, removing all superfluous material such as paint residue, welding beads, burrs, etc.Care should be taken not to let the solvent infiltrate into the rotary support during cleaning. Do not use solvents that damage sealing materials.The mounting surface should be dry and free of lubricant before assembly.Measures should be taken to protect workers and the environment.

In extreme cases after long term storage bearings may need professionally reconditioning before

installation.When unwrapping, care must be taken not to cut and damage the integral seals.

The supporting surfaces must have a flat machined surface and be rigid enough to eliminate torsional buckling under load that would affect the smooth operation of the single row ball slewing ring bearing. The thickness of the supporting plates should be no less than that indicated below – which is offered as a rough approximation only.

Home | About Us | Products | News | Application | Support | Contact Us